Hot Products

YSX500D 50kW DR system set up and put into service in Cambodia.

YSENMED YSX500D 50kW digital x-ray system has been successfully set up and put into service in a hospital in Cambodia.

YSX056-PE serving as a vehicle-mounted x-ray in the Philippines

YSX056-PE 5.6kW portable x-ray unit has been adapted to fit on a truck, to provide mobile x-ray examination service for remote communities in the Philippines.

X Ray Machine To Zimbabwe

x ray machine, 50KW x ray machine

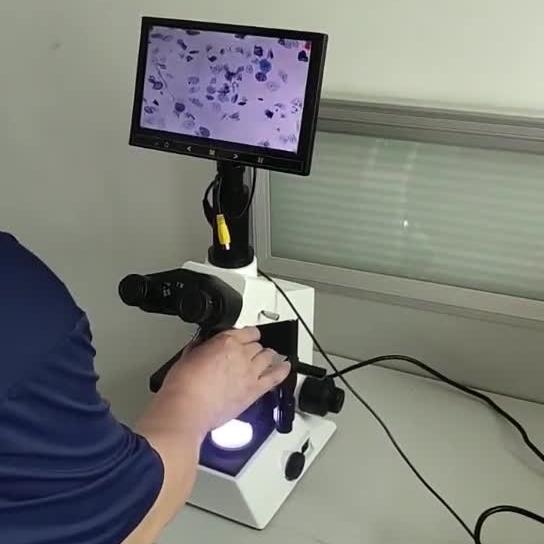

Microscope To Malawi

Achromatic objectives: 4X、10X、40X(S), 100X(S、Oil) Wide field eyepiece: WF10X(WF16X for option) Eyepiece head: Sliding binocular head inclined at 45° Stage: Double layer mechanical stage size 140X140mm, moving range 75X45mm Focusing: Coaxial coarse and

From Ashing to Firing: The Many Uses of a Muffle Furnace in Scientific Labs

Views : 1104

Update time : 2024-11-26 16:37:00

When you step into a scientific lab, you might be greeted by a plethora of equipment, each serving a unique purpose. Among these, the muffle furnace stands out as a silent powerhouse, often overlooked but incredibly versatile. From ashing samples to firing ceramics, this unassuming device plays a crucial role in various scientific applications. In this article, we'll dive deep into the world of muffle furnaces, exploring their uses, benefits, and some tips to get the most out of them.

What is a Muffle Furnace?

A muffle furnace is an electric furnace designed to provide a controlled atmosphere for heating materials. Unlike traditional furnaces, a muffle furnace has a chamber that isolates the sample from the combustion products, ensuring purity and precision in experiments. This makes it an essential tool for many scientific applications.

How Does a Muffle Furnace Work?

At its core, a muffle furnace operates by heating materials in a closed chamber. The heating elements, usually made of high-temperature resistant materials, surround the chamber, allowing for even distribution of heat. This design minimizes temperature fluctuations and prevents contamination from combustion gases.

The Heating Process

When you set the desired temperature, the furnace gradually increases heat until it reaches the specified level. This gradual heating is crucial for processes like ashing, where rapid temperature changes can lead to inaccurate results.

The Many Uses of a Muffle Furnace

1. Ashing Samples

One of the primary uses of a muffle furnace is ashing. This process involves burning off organic materials in a sample, leaving behind inorganic residues. It's commonly used in environmental science to analyze soil and plant samples.

2. Material Testing

In material science, a muffle furnace is indispensable for testing the properties of various materials. Researchers can heat samples to determine their melting points, thermal stability, and other critical characteristics.

3. Firing Ceramics

If you've ever marveled at a beautifully crafted ceramic piece, chances are it was fired in a muffle furnace. This process involves heating clay to high temperatures, transforming it into a durable material. The controlled environment of a muffle furnace ensures even firing and prevents cracking.

4. Metal Sample Preparation

For metallurgists, preparing metal samples for analysis is a crucial step. A muffle furnace can be used to remove impurities and prepare samples for further testing, such as X-ray fluorescence (XRF) analysis.

5. Glass Melting

Artists and scientists alike utilize muffle furnaces for melting glass. The precise temperature control allows for the creation of intricate glass designs, whether for art or scientific applications.

6. Combustion Analysis

In chemistry, combustion analysis is vital for determining the elemental composition of a substance. A muffle furnace provides the ideal environment for burning samples and collecting gases for analysis.

7. Sintering

Sintering is a process where powdered materials are heated below their melting point to form a solid mass. This technique is commonly used in the production of ceramics and metals, and a muffle furnace is perfect for achieving the necessary temperatures.

8. Calcination

Calcination involves heating materials to induce chemical changes, often used in the production of lime from limestone. The muffle furnace provides the high temperatures required for this transformation.

9. Biological Sample Preparation

In biological research, preparing samples for analysis is crucial. A muffle furnace can be used to ash biological samples, allowing researchers to study the inorganic components without interference from organic matter.

10. Environmental Testing

Environmental scientists use muffle furnaces to analyze pollutants in soil and water samples. By ashing samples, they can determine the concentration of heavy metals and other harmful substances.

11. Forensic Analysis

In forensic science, a muffle furnace can assist in the analysis of evidence. Whether it's analyzing residues from a crime scene or testing materials, the controlled environment ensures accurate results.

12. Research and Development

In R&D labs, muffle furnaces are essential for developing new materials and processes. Researchers can experiment with different heating profiles to optimize their results.

13. Jewelry Making

For jewelers, a muffle furnace can be used to melt metals and create intricate designs. The precise temperature control allows for the safe melting of precious metals without contamination.

14. Educational Purposes

In educational settings, muffle furnaces are often used to teach students about material properties, chemical reactions, and the importance of controlled environments in experiments.

15. Calibration of Instruments

Lastly, muffle furnaces are sometimes used to calibrate other laboratory instruments. By providing a stable heat source, they help ensure that temperature-sensitive equipment operates accurately.

Benefits of Using a Muffle Furnace

Precision and Control

One of the standout features of a muffle furnace is its ability to provide precise temperature control. This is crucial for experiments where even slight variations can lead to significant differences in results.

Versatility

As highlighted, muffle furnaces are incredibly versatile. From ashing to firing ceramics, their range of applications makes them a valuable asset in any lab.

Safety

Muffle furnaces are designed with safety in mind. The enclosed design minimizes the risk of exposure to harmful gases and allows for safer handling of high-temperature materials.

Energy Efficiency

Modern muffle furnaces are designed to be energy-efficient, reducing operational costs while maintaining high performance.

Tips for Using a Muffle Furnace

1. Always Follow Manufacturer Guidelines

Every muffle furnace is different, so it's essential to read the manufacturer's instructions before use. This ensures you're operating the device safely and effectively.

2. Regular Maintenance

Like any piece of equipment, regular maintenance is key to ensuring the longevity of your muffle furnace. Clean the chamber regularly and check for any signs of wear and tear.

3. Use Proper Safety Gear

When working with a muffle furnace, always wear appropriate safety gear, including gloves and goggles, to protect yourself from heat and potential hazards.

4. Monitor Temperature Closely

Even though muffle furnaces offer precise control, it's wise to monitor the temperature throughout the process. This helps catch any discrepancies early.

5. Experiment with Heating Profiles

Don't be afraid to experiment! Different materials may require unique heating profiles, so take notes and adjust your approach based on your findings.

Conclusion

The muffle furnace may not be the flashiest piece of equipment in a lab, but its versatility and precision make it an invaluable tool for scientists across various fields. From ashing samples to firing ceramics, it plays a pivotal role in ensuring accurate and reliable results. By understanding its many uses and following best practices, you can unlock the full potential of this remarkable device. So, the next time you step into a lab, take a moment to appreciate the silent workhorse that is the muffle furnace—it's doing more than you might think!

What is a Muffle Furnace?

A muffle furnace is an electric furnace designed to provide a controlled atmosphere for heating materials. Unlike traditional furnaces, a muffle furnace has a chamber that isolates the sample from the combustion products, ensuring purity and precision in experiments. This makes it an essential tool for many scientific applications.

How Does a Muffle Furnace Work?

At its core, a muffle furnace operates by heating materials in a closed chamber. The heating elements, usually made of high-temperature resistant materials, surround the chamber, allowing for even distribution of heat. This design minimizes temperature fluctuations and prevents contamination from combustion gases.

The Heating Process

When you set the desired temperature, the furnace gradually increases heat until it reaches the specified level. This gradual heating is crucial for processes like ashing, where rapid temperature changes can lead to inaccurate results.

The Many Uses of a Muffle Furnace

1. Ashing Samples

One of the primary uses of a muffle furnace is ashing. This process involves burning off organic materials in a sample, leaving behind inorganic residues. It's commonly used in environmental science to analyze soil and plant samples.

2. Material Testing

In material science, a muffle furnace is indispensable for testing the properties of various materials. Researchers can heat samples to determine their melting points, thermal stability, and other critical characteristics.

3. Firing Ceramics

If you've ever marveled at a beautifully crafted ceramic piece, chances are it was fired in a muffle furnace. This process involves heating clay to high temperatures, transforming it into a durable material. The controlled environment of a muffle furnace ensures even firing and prevents cracking.

4. Metal Sample Preparation

For metallurgists, preparing metal samples for analysis is a crucial step. A muffle furnace can be used to remove impurities and prepare samples for further testing, such as X-ray fluorescence (XRF) analysis.

5. Glass Melting

Artists and scientists alike utilize muffle furnaces for melting glass. The precise temperature control allows for the creation of intricate glass designs, whether for art or scientific applications.

6. Combustion Analysis

In chemistry, combustion analysis is vital for determining the elemental composition of a substance. A muffle furnace provides the ideal environment for burning samples and collecting gases for analysis.

7. Sintering

Sintering is a process where powdered materials are heated below their melting point to form a solid mass. This technique is commonly used in the production of ceramics and metals, and a muffle furnace is perfect for achieving the necessary temperatures.

8. Calcination

Calcination involves heating materials to induce chemical changes, often used in the production of lime from limestone. The muffle furnace provides the high temperatures required for this transformation.

9. Biological Sample Preparation

In biological research, preparing samples for analysis is crucial. A muffle furnace can be used to ash biological samples, allowing researchers to study the inorganic components without interference from organic matter.

10. Environmental Testing

Environmental scientists use muffle furnaces to analyze pollutants in soil and water samples. By ashing samples, they can determine the concentration of heavy metals and other harmful substances.

11. Forensic Analysis

In forensic science, a muffle furnace can assist in the analysis of evidence. Whether it's analyzing residues from a crime scene or testing materials, the controlled environment ensures accurate results.

12. Research and Development

In R&D labs, muffle furnaces are essential for developing new materials and processes. Researchers can experiment with different heating profiles to optimize their results.

13. Jewelry Making

For jewelers, a muffle furnace can be used to melt metals and create intricate designs. The precise temperature control allows for the safe melting of precious metals without contamination.

14. Educational Purposes

In educational settings, muffle furnaces are often used to teach students about material properties, chemical reactions, and the importance of controlled environments in experiments.

15. Calibration of Instruments

Lastly, muffle furnaces are sometimes used to calibrate other laboratory instruments. By providing a stable heat source, they help ensure that temperature-sensitive equipment operates accurately.

Benefits of Using a Muffle Furnace

Precision and Control

One of the standout features of a muffle furnace is its ability to provide precise temperature control. This is crucial for experiments where even slight variations can lead to significant differences in results.

Versatility

As highlighted, muffle furnaces are incredibly versatile. From ashing to firing ceramics, their range of applications makes them a valuable asset in any lab.

Safety

Muffle furnaces are designed with safety in mind. The enclosed design minimizes the risk of exposure to harmful gases and allows for safer handling of high-temperature materials.

Energy Efficiency

Modern muffle furnaces are designed to be energy-efficient, reducing operational costs while maintaining high performance.

Tips for Using a Muffle Furnace

1. Always Follow Manufacturer Guidelines

Every muffle furnace is different, so it's essential to read the manufacturer's instructions before use. This ensures you're operating the device safely and effectively.

2. Regular Maintenance

Like any piece of equipment, regular maintenance is key to ensuring the longevity of your muffle furnace. Clean the chamber regularly and check for any signs of wear and tear.

3. Use Proper Safety Gear

When working with a muffle furnace, always wear appropriate safety gear, including gloves and goggles, to protect yourself from heat and potential hazards.

4. Monitor Temperature Closely

Even though muffle furnaces offer precise control, it's wise to monitor the temperature throughout the process. This helps catch any discrepancies early.

5. Experiment with Heating Profiles

Don't be afraid to experiment! Different materials may require unique heating profiles, so take notes and adjust your approach based on your findings.

Conclusion

The muffle furnace may not be the flashiest piece of equipment in a lab, but its versatility and precision make it an invaluable tool for scientists across various fields. From ashing samples to firing ceramics, it plays a pivotal role in ensuring accurate and reliable results. By understanding its many uses and following best practices, you can unlock the full potential of this remarkable device. So, the next time you step into a lab, take a moment to appreciate the silent workhorse that is the muffle furnace—it's doing more than you might think!

Related News

Read More >>

Is an Infant Radiant Warmer Good for Babies' Health?

Is an Infant Radiant Warmer Good for Babies' Health?

Apr .13.2025

What exactly is the infant radiant warmer, and how does it contribute to a baby's health? Let's dive into this topic and explore the ins and outs of infant radiant warmers.

What is an Infant Radiant Warmer?

What is an Infant Radiant Warmer?

Apr .12.2025

One of the unsung heroes in neonatal care is the infant radiant warmer. But what exactly is it? Let's dive into the world of infant care and explore the ins and outs of this vital device.

Introduction video of YSENMED YSXWJ-BX301B Digital Biological Microscope.

Introduction video of YSENMED YSXWJ-BX301B Digital Biological Microscope.

Apr .01.2025

Here we share the introduction video of YSENMED YSXWJ-BX301B Digital Biological Microscope.

YSDR-VET320 veterinary DR & YSB-DU10V color ultrasound serving well in Kiram Veterinary Surgery in Uganda

YSDR-VET320 veterinary DR & YSB-DU10V color ultrasound serving well in Kiram Veterinary Surgery in Uganda

Mar .31.2025

Kiram Veterinary Surgery in Uganda shares the clear images they have got from YSDR-VET320 veterinary digital x-ray system and YSB-DU10V vet color ultrasound machine.