Hot Products

YSX500D 50kW DR system set up and put into service in Cambodia.

YSENMED YSX500D 50kW digital x-ray system has been successfully set up and put into service in a hospital in Cambodia.

YSX056-PE serving as a vehicle-mounted x-ray in the Philippines

YSX056-PE 5.6kW portable x-ray unit has been adapted to fit on a truck, to provide mobile x-ray examination service for remote communities in the Philippines.

X Ray Machine To Zimbabwe

x ray machine, 50KW x ray machine

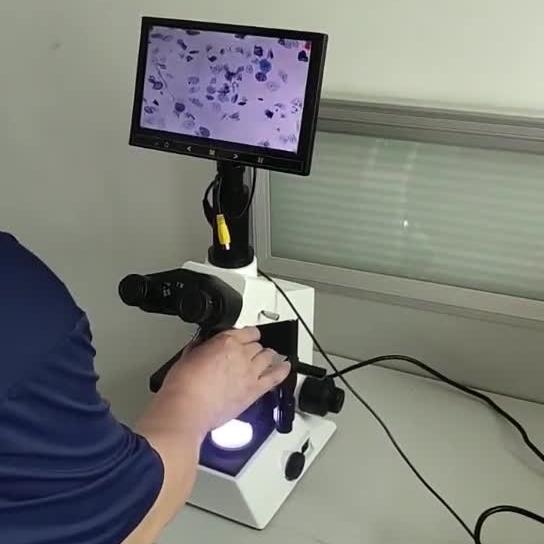

Microscope To Malawi

Achromatic objectives: 4X、10X、40X(S), 100X(S、Oil) Wide field eyepiece: WF10X(WF16X for option) Eyepiece head: Sliding binocular head inclined at 45° Stage: Double layer mechanical stage size 140X140mm, moving range 75X45mm Focusing: Coaxial coarse and

Unlocking the Power of Low-Temperature Plasma: A Guide to 240L Sterilizers

Views : 2473

Update time : 2024-04-14 15:17:00

In the world of medical equipment sterilization, advancements are continually being made to improve efficiency, efficacy, and safety. One such groundbreaking technology that has emerged is low-temperature plasma sterilization. In this comprehensive guide, we'll explore the ins and outs of low-temperature plasma sterilization and delve deep into the specifics of 240L sterilizers, shedding light on their role in revolutionizing the sterilization process.

1. Understanding Low-Temperature Plasma Sterilization

What is Low-Temperature Plasma?

Low-temperature plasma is often referred to as the fourth state of matter, distinct from solids, liquids, and gases. It consists of a mix of ions, radicals, and neutral species, created when electrons are unbound from atoms. This unique state of matter possesses remarkable sterilization capabilities due to its ability to penetrate intricate surfaces and effectively neutralize microorganisms.

How Does it Work?

Low-temperature plasma sterilization works by exposing items to a combination of hydrogen peroxide vapor and plasma. The plasma generates highly reactive radicals that target and disrupt the molecular structure of microorganisms, rendering them inactive. Unlike traditional sterilization methods such as autoclaving, which rely on heat and moisture, low-temperature plasma sterilization operates at temperatures as low as 35°C, making it suitable for heat-sensitive materials.

Benefits of Low-Temperature Plasma Sterilization

- Compatibility: Low-temperature plasma sterilization is compatible with a wide range of materials, including plastics, rubber, and electronics, making it versatile for various applications.

- Efficacy: It effectively eliminates a broad spectrum of microorganisms, including bacteria, viruses, and spores, ensuring a high level of sterility.

- Short Cycle Times: With rapid cycle times ranging from 25 to 75 minutes, low-temperature plasma sterilizers offer quick turnaround, enhancing operational efficiency in healthcare facilities.

2. Introducing the 240L Sterilizer

What is a 240L Sterilizer?

A 240L sterilizer is a state-of-the-art medical device designed for large-scale sterilization of medical instruments and equipment. The term "240L" refers to the chamber size of the sterilizer, indicating its capacity to accommodate up to 240 liters of load.

Features of 240L Sterilizers

- Large Capacity: With a spacious chamber, 240L sterilizers can sterilize a substantial quantity of instruments in a single cycle, reducing the need for multiple runs and optimizing workflow efficiency.

- Advanced Control System: Equipped with intuitive touch-screen interfaces and customizable cycle parameters, these sterilizers offer ease of operation and precise control over sterilization processes.

- Comprehensive Safety Features: From automatic door locks and pressure sensors to leak detection systems, 240L sterilizers prioritize user safety and ensure compliance with regulatory standards.

- Environmentally Friendly: Low-temperature plasma sterilization is eco-friendly, as it does not produce harmful emissions or waste, aligning with sustainable healthcare practices.

3. Applications of 240L Sterilizers

Healthcare Settings

In hospitals, clinics, and medical laboratories, maintaining a sterile environment is crucial for patient safety and infection control. 240L sterilizers are extensively used for sterilizing surgical instruments, endoscopes, implants, and other critical medical devices, ensuring they are free from harmful pathogens before use.

Research Facilities

Research facilities handling sensitive materials such as cell cultures, tissue samples, and laboratory equipment rely on 240L sterilizers to maintain contamination-free environments. By sterilizing equipment and materials, these sterilizers preserve the integrity of experiments and ensure reliable research outcomes.

Pharmaceutical Industry

In the pharmaceutical manufacturing process, maintaining sterility is essential to ensure the safety and efficacy of pharmaceutical products. 240L sterilizers play a crucial role in sterilizing production equipment, containers, and packaging materials, adhering to strict regulatory requirements and quality standards.

4. Tips for Optimal Performance

Proper Loading

Proper loading of items inside the sterilization chamber is essential to ensure thorough sterilization. Items should be arranged to allow for adequate airflow and plasma distribution, avoiding overcrowding or blocking of vents.

Routine Maintenance

Regular maintenance and calibration are necessary to keep 240L sterilizers operating at peak performance. This includes periodic inspections, cleaning of internal components, and calibration of sensors and controls. Following manufacturer recommendations for maintenance ensures the longevity and reliability of the equipment.

Training and Education

Proper training of personnel involved in operating 240L sterilizers is crucial to ensure safe and effective use. Training should cover equipment operation, cycle parameters, loading procedures, and troubleshooting techniques. Well-trained staff are better equipped to handle sterilization processes efficiently and minimize the risk of errors.

5. Conclusion

Low-temperature plasma sterilization technology, exemplified by 240L sterilizers, represents a significant advancement in the field of medical equipment sterilization. With their advanced features, large capacity, and eco-friendly operation, these sterilizers offer a reliable solution for achieving high levels of sterility in healthcare, research, and pharmaceutical settings. By embracing this innovative technology and implementing best practices for operation and maintenance, healthcare facilities can enhance patient safety, improve workflow efficiency, and contribute to overall quality of care. Unlock the power of low-temperature plasma with 240L sterilizers, and experience a new standard of sterilization excellence.

FAQs

Can low-temperature plasma sterilization effectively kill all types of microorganisms?

Low-temperature plasma sterilization is highly effective against a broad spectrum of microorganisms, including bacteria, viruses, and spores. However, its efficacy may vary depending on factors such as the type of microorganism, the load being sterilized, and the specific parameters of the sterilization cycle.

How does low-temperature plasma sterilization compare to other sterilization methods in terms of material compatibility?

Low-temperature plasma sterilization offers excellent material compatibility, particularly for heat-sensitive materials such as plastics, rubber, and electronics. Unlike methods like autoclaving, which use heat and moisture, low-temperature plasma sterilization operates at temperatures as low as 35°C, minimizing the risk of damage to delicate instruments and equipment.

What safety features are typically included in 240L sterilizers?

240L sterilizers are equipped with comprehensive safety features to ensure user safety and compliance with regulatory standards. These may include automatic door locks during operation, pressure sensors to monitor chamber integrity, leak detection systems, and alarms to alert users of any abnormalities during the sterilization process.

How often should routine maintenance be performed on a 240L sterilizer?

Routine maintenance of a 240L sterilizer should be performed according to the manufacturer's recommendations. This typically involves regular inspections, cleaning of internal components, calibration of sensors and controls, and any necessary repairs or replacements. Adhering to a structured maintenance schedule helps ensure the sterilizer operates reliably and consistently.

Can 240L sterilizers be used in pharmaceutical manufacturing facilities?

Yes, 240L sterilizers are commonly used in pharmaceutical manufacturing facilities to sterilize production equipment, containers, and packaging materials. These sterilizers play a crucial role in maintaining sterility throughout the manufacturing process, ensuring the safety and efficacy of pharmaceutical products.

1. Understanding Low-Temperature Plasma Sterilization

What is Low-Temperature Plasma?

Low-temperature plasma is often referred to as the fourth state of matter, distinct from solids, liquids, and gases. It consists of a mix of ions, radicals, and neutral species, created when electrons are unbound from atoms. This unique state of matter possesses remarkable sterilization capabilities due to its ability to penetrate intricate surfaces and effectively neutralize microorganisms.

How Does it Work?

Low-temperature plasma sterilization works by exposing items to a combination of hydrogen peroxide vapor and plasma. The plasma generates highly reactive radicals that target and disrupt the molecular structure of microorganisms, rendering them inactive. Unlike traditional sterilization methods such as autoclaving, which rely on heat and moisture, low-temperature plasma sterilization operates at temperatures as low as 35°C, making it suitable for heat-sensitive materials.

Benefits of Low-Temperature Plasma Sterilization

- Compatibility: Low-temperature plasma sterilization is compatible with a wide range of materials, including plastics, rubber, and electronics, making it versatile for various applications.

- Efficacy: It effectively eliminates a broad spectrum of microorganisms, including bacteria, viruses, and spores, ensuring a high level of sterility.

- Short Cycle Times: With rapid cycle times ranging from 25 to 75 minutes, low-temperature plasma sterilizers offer quick turnaround, enhancing operational efficiency in healthcare facilities.

2. Introducing the 240L Sterilizer

What is a 240L Sterilizer?

A 240L sterilizer is a state-of-the-art medical device designed for large-scale sterilization of medical instruments and equipment. The term "240L" refers to the chamber size of the sterilizer, indicating its capacity to accommodate up to 240 liters of load.

Features of 240L Sterilizers

- Large Capacity: With a spacious chamber, 240L sterilizers can sterilize a substantial quantity of instruments in a single cycle, reducing the need for multiple runs and optimizing workflow efficiency.

- Advanced Control System: Equipped with intuitive touch-screen interfaces and customizable cycle parameters, these sterilizers offer ease of operation and precise control over sterilization processes.

- Comprehensive Safety Features: From automatic door locks and pressure sensors to leak detection systems, 240L sterilizers prioritize user safety and ensure compliance with regulatory standards.

- Environmentally Friendly: Low-temperature plasma sterilization is eco-friendly, as it does not produce harmful emissions or waste, aligning with sustainable healthcare practices.

3. Applications of 240L Sterilizers

Healthcare Settings

In hospitals, clinics, and medical laboratories, maintaining a sterile environment is crucial for patient safety and infection control. 240L sterilizers are extensively used for sterilizing surgical instruments, endoscopes, implants, and other critical medical devices, ensuring they are free from harmful pathogens before use.

Research Facilities

Research facilities handling sensitive materials such as cell cultures, tissue samples, and laboratory equipment rely on 240L sterilizers to maintain contamination-free environments. By sterilizing equipment and materials, these sterilizers preserve the integrity of experiments and ensure reliable research outcomes.

Pharmaceutical Industry

In the pharmaceutical manufacturing process, maintaining sterility is essential to ensure the safety and efficacy of pharmaceutical products. 240L sterilizers play a crucial role in sterilizing production equipment, containers, and packaging materials, adhering to strict regulatory requirements and quality standards.

4. Tips for Optimal Performance

Proper Loading

Proper loading of items inside the sterilization chamber is essential to ensure thorough sterilization. Items should be arranged to allow for adequate airflow and plasma distribution, avoiding overcrowding or blocking of vents.

Routine Maintenance

Regular maintenance and calibration are necessary to keep 240L sterilizers operating at peak performance. This includes periodic inspections, cleaning of internal components, and calibration of sensors and controls. Following manufacturer recommendations for maintenance ensures the longevity and reliability of the equipment.

Training and Education

Proper training of personnel involved in operating 240L sterilizers is crucial to ensure safe and effective use. Training should cover equipment operation, cycle parameters, loading procedures, and troubleshooting techniques. Well-trained staff are better equipped to handle sterilization processes efficiently and minimize the risk of errors.

5. Conclusion

Low-temperature plasma sterilization technology, exemplified by 240L sterilizers, represents a significant advancement in the field of medical equipment sterilization. With their advanced features, large capacity, and eco-friendly operation, these sterilizers offer a reliable solution for achieving high levels of sterility in healthcare, research, and pharmaceutical settings. By embracing this innovative technology and implementing best practices for operation and maintenance, healthcare facilities can enhance patient safety, improve workflow efficiency, and contribute to overall quality of care. Unlock the power of low-temperature plasma with 240L sterilizers, and experience a new standard of sterilization excellence.

FAQs

Can low-temperature plasma sterilization effectively kill all types of microorganisms?

Low-temperature plasma sterilization is highly effective against a broad spectrum of microorganisms, including bacteria, viruses, and spores. However, its efficacy may vary depending on factors such as the type of microorganism, the load being sterilized, and the specific parameters of the sterilization cycle.

How does low-temperature plasma sterilization compare to other sterilization methods in terms of material compatibility?

Low-temperature plasma sterilization offers excellent material compatibility, particularly for heat-sensitive materials such as plastics, rubber, and electronics. Unlike methods like autoclaving, which use heat and moisture, low-temperature plasma sterilization operates at temperatures as low as 35°C, minimizing the risk of damage to delicate instruments and equipment.

What safety features are typically included in 240L sterilizers?

240L sterilizers are equipped with comprehensive safety features to ensure user safety and compliance with regulatory standards. These may include automatic door locks during operation, pressure sensors to monitor chamber integrity, leak detection systems, and alarms to alert users of any abnormalities during the sterilization process.

How often should routine maintenance be performed on a 240L sterilizer?

Routine maintenance of a 240L sterilizer should be performed according to the manufacturer's recommendations. This typically involves regular inspections, cleaning of internal components, calibration of sensors and controls, and any necessary repairs or replacements. Adhering to a structured maintenance schedule helps ensure the sterilizer operates reliably and consistently.

Can 240L sterilizers be used in pharmaceutical manufacturing facilities?

Yes, 240L sterilizers are commonly used in pharmaceutical manufacturing facilities to sterilize production equipment, containers, and packaging materials. These sterilizers play a crucial role in maintaining sterility throughout the manufacturing process, ensuring the safety and efficacy of pharmaceutical products.

Related News

Read More >>

Introduction video of YSENMED YSXWJ-BX301B Digital Biological Microscope.

Introduction video of YSENMED YSXWJ-BX301B Digital Biological Microscope.

Apr .01.2025

Here we share the introduction video of YSENMED YSXWJ-BX301B Digital Biological Microscope.

YSDR-VET320 veterinary DR & YSB-DU10V color ultrasound serving well in Kiram Veterinary Surgery in Uganda

YSDR-VET320 veterinary DR & YSB-DU10V color ultrasound serving well in Kiram Veterinary Surgery in Uganda

Mar .31.2025

Kiram Veterinary Surgery in Uganda shares the clear images they have got from YSDR-VET320 veterinary digital x-ray system and YSB-DU10V vet color ultrasound machine.

YSENMED YSFPD-R1012C mammo flat panel detector introduced and set up in a hospital in Senegal

YSENMED YSFPD-R1012C mammo flat panel detector introduced and set up in a hospital in Senegal

Mar .30.2025

Senegalese hospital has upgraded its analog mammography x-ray system with YSFPD-R1012C mammo flat panel detector, and the images come out clear.

YSX-mDR5A 5.3kW mobile DR system working fine in a clinic in Gambia

YSX-mDR5A 5.3kW mobile DR system working fine in a clinic in Gambia

Mar .29.2025

YSENMED YSX-mDR5A 5.3kW mobile digital x-ray unit is working well in a clinic in Gambia.