Categorias

Radiologia Médica

Processadores de filme automático

Processadores de filme manual

Filmes de raio-X

Cassetes de Raio-X

Telas de intensificação

Luzes da câmara escura

Soluções de desenvolvimento de filmes

Secador de filme

Espectadores de filmes

Cabides de filme

Marcadores de filme

Caixas de transferência de filme

Caixas de armazenamento de filme

Estandes de peito

Dosímetros de raios-X

Mesas de raio-X

Sala de raio-x

Gerador de raios X

Equipamento não magnético de ressonância magnética

Processadores de filme automático

Processadores de filme manual

Filmes de raio-X

Cassetes de Raio-X

Telas de intensificação

Luzes da câmara escura

Soluções de desenvolvimento de filmes

Secador de filme

Espectadores de filmes

Cabides de filme

Marcadores de filme

Caixas de transferência de filme

Caixas de armazenamento de filme

Estandes de peito

Dosímetros de raios-X

Mesas de raio-X

Sala de raio-x

Gerador de raios X

Equipamento não magnético de ressonância magnética

Produtos quentes

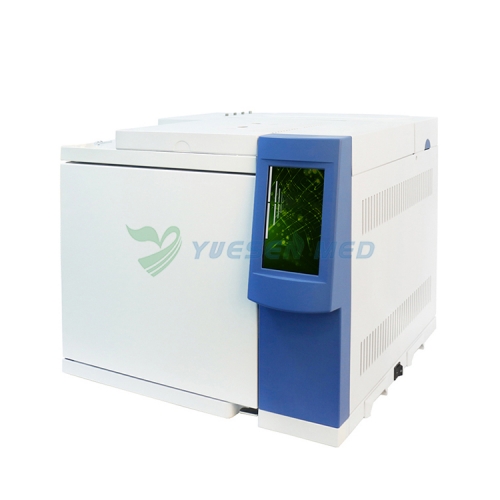

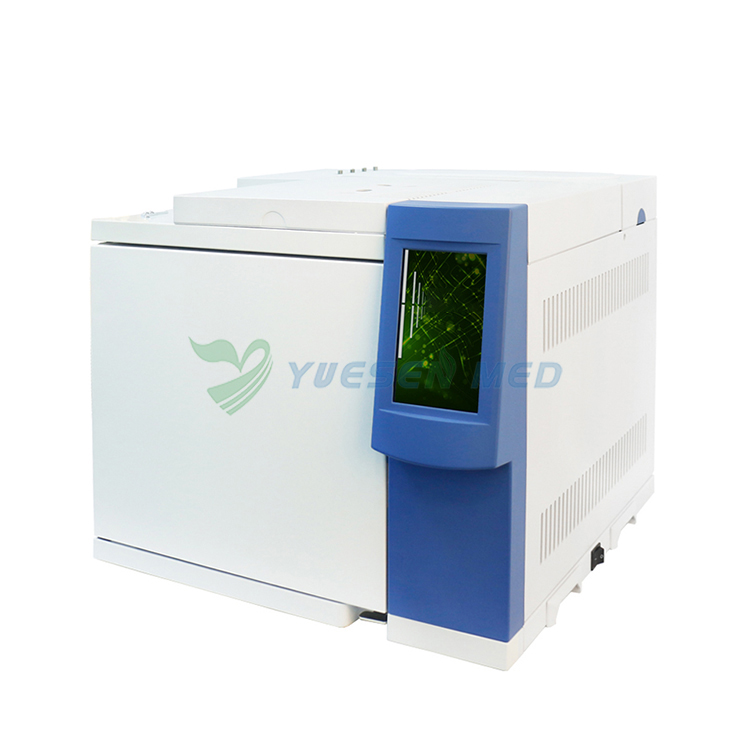

Analisador de cromatografia de gás YSTE-GC112N

Item número.: YSTE-GC112N

O analisador de cromatografia de gás YSTE-GC112N é um dos instrumentos analíticos amplamente usados. Tornou-se um instrumento analítico ideal para separação ou análise em vários campos.

| Parâmetros do produto | |

| Marca: | YSENMED |

| MOQ: | 1 |

| Pacote: | Wooden Package |

| Vindo de: | Guangzhou |

| Tempo de espera: | 3 days |

| Costumização: | Customized packaging |

Descrição

YSTE-GC112N Gas chromatography analyzer is one of widely used analytical instruments. It has become an ideal analytical instrument for separation or analysis in various fields.

Technical Features

● Standard PC control software, built-in chromatographic workstation, achieve PC side reverse control and touch screen synchronous bidirectional control.

● 7-inch color touch screen, carrier/hydrogen/air channel flow (pressure) digital display.

● Gas shortage alarm protection function; Heating control protection function (when opening the door of the column box, the motor of the column box fan and the heating system will shut down automatically).

● Split flow/split ratio can be automatically controlled to save carrier gas.

● Configure automatic sampler installation and positioning interface to match automatic sampler of various specifications.

● The multi-core, 32-bit embedded hardware system ensures the reliable operation of the instrument.

● One-button start function, with 20 groups of sample test mode memory function.

● Using logarithmic amplifier, detection signal no cut-off value, good peak shape, extensible synchronous external trigger function, can be started by external signals (automatic sampler, thermal analyzer, etc.) at the same time the host and workstation.

● It has perfect system self-check function and fault automatic identification function.

● With 8 external event extension function interface, can be selected with various function control valves, and according to their own set time sequence work.

● RS232 communication port and LAM network port, and the configuration of data acquisition card.

Oven

● Content product: 22L

● Temperature control range: 5℃ ~ 400℃ at room temperature

● Temperature control accuracy: ±0.1℃

● Heating rate: 0.1 ~ 60℃ / min

● Program temperature rise order: 9

● Program heating repeatability: ≤ 2%

● Cooling way: open the door after

● Cooling speed: ≤10 mins (250℃ ~ 50℃)

Control Software Function

● Column temperature box control

● Detector control

● Injector control

● Map display

Sampler Injector

● Temperature control range: 7℃ ~ 420℃ at room temperature

● Temperature control method: independent temperature control

● Carrier gas flow control mode: constant pressure

● Number of simultaneous installations: 3 at most

● Type of injection unit: filling column, shunt

● Split ratio: split ratio display

● Cylinder pressure range: 0 ~ 400kPa

● Cylinder pressure control accuracy: 0.1kPa

● Flow setting range: H2 0 ~ 200ml / min N2 0 ~ 150ml / min

Detector

● FID, TCD optional

● Temperature control: Max. 420℃

● Number of simultaneous installations: 2 at most

● Ignition function: automatic

● Hydrogen flame ionization detector (FID)

Detection limit: ≤ 3×10-12 g/s (n-hexadecane)

Baseline noise: ≤ 5× 10-14A

Baseline drift: ≤ 6× 10-13A

Dynamic range: 107

RSD: 3% or less

● Thermal conductivity detector (TCD) :

Sensitivity: 5000mV•mL/mg (n-cetane)

Baseline noise: ≤ 0.05 mV

Baseline drift: ≤ 0.15mV / 30min

Dynamic range: 105

● Supply voltage: AC220V±22V, 50Hz±0.5Hz

● Power: 3000W

Optional

● N2000 chromatography workstation

● Packed column

● Capillary column

Technical Features

● Standard PC control software, built-in chromatographic workstation, achieve PC side reverse control and touch screen synchronous bidirectional control.

● 7-inch color touch screen, carrier/hydrogen/air channel flow (pressure) digital display.

● Gas shortage alarm protection function; Heating control protection function (when opening the door of the column box, the motor of the column box fan and the heating system will shut down automatically).

● Split flow/split ratio can be automatically controlled to save carrier gas.

● Configure automatic sampler installation and positioning interface to match automatic sampler of various specifications.

● The multi-core, 32-bit embedded hardware system ensures the reliable operation of the instrument.

● One-button start function, with 20 groups of sample test mode memory function.

● Using logarithmic amplifier, detection signal no cut-off value, good peak shape, extensible synchronous external trigger function, can be started by external signals (automatic sampler, thermal analyzer, etc.) at the same time the host and workstation.

● It has perfect system self-check function and fault automatic identification function.

● With 8 external event extension function interface, can be selected with various function control valves, and according to their own set time sequence work.

● RS232 communication port and LAM network port, and the configuration of data acquisition card.

Oven

● Content product: 22L

● Temperature control range: 5℃ ~ 400℃ at room temperature

● Temperature control accuracy: ±0.1℃

● Heating rate: 0.1 ~ 60℃ / min

● Program temperature rise order: 9

● Program heating repeatability: ≤ 2%

● Cooling way: open the door after

● Cooling speed: ≤10 mins (250℃ ~ 50℃)

Control Software Function

● Column temperature box control

● Detector control

● Injector control

● Map display

Sampler Injector

● Temperature control range: 7℃ ~ 420℃ at room temperature

● Temperature control method: independent temperature control

● Carrier gas flow control mode: constant pressure

● Number of simultaneous installations: 3 at most

● Type of injection unit: filling column, shunt

● Split ratio: split ratio display

● Cylinder pressure range: 0 ~ 400kPa

● Cylinder pressure control accuracy: 0.1kPa

● Flow setting range: H2 0 ~ 200ml / min N2 0 ~ 150ml / min

Detector

● FID, TCD optional

● Temperature control: Max. 420℃

● Number of simultaneous installations: 2 at most

● Ignition function: automatic

● Hydrogen flame ionization detector (FID)

Detection limit: ≤ 3×10-12 g/s (n-hexadecane)

Baseline noise: ≤ 5× 10-14A

Baseline drift: ≤ 6× 10-13A

Dynamic range: 107

RSD: 3% or less

● Thermal conductivity detector (TCD) :

Sensitivity: 5000mV•mL/mg (n-cetane)

Baseline noise: ≤ 0.05 mV

Baseline drift: ≤ 0.15mV / 30min

Dynamic range: 105

● Supply voltage: AC220V±22V, 50Hz±0.5Hz

● Power: 3000W

Optional

● N2000 chromatography workstation

● Packed column

● Capillary column

YOUR MAY ALSO LIKE ...