Categorias

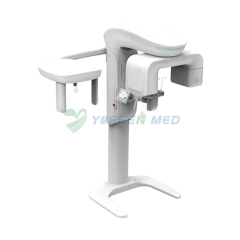

Radiologia Médica

Processadores de filme automático

Processadores de filme manual

Filmes de raio-X

Cassetes de Raio-X

Telas de intensificação

Luzes da câmara escura

Soluções de desenvolvimento de filmes

Secador de filme

Espectadores de filmes

Cabides de filme

Marcadores de filme

Caixas de transferência de filme

Caixas de armazenamento de filme

Estandes de peito

Dosímetros de raios-X

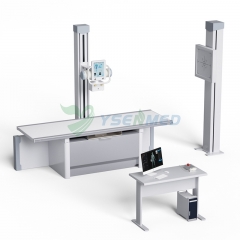

Mesas de raio-X

Sala de raio-x

Gerador de raios X

Equipamento não magnético de ressonância magnética

Processadores de filme automático

Processadores de filme manual

Filmes de raio-X

Cassetes de Raio-X

Telas de intensificação

Luzes da câmara escura

Soluções de desenvolvimento de filmes

Secador de filme

Espectadores de filmes

Cabides de filme

Marcadores de filme

Caixas de transferência de filme

Caixas de armazenamento de filme

Estandes de peito

Dosímetros de raios-X

Mesas de raio-X

Sala de raio-x

Gerador de raios X

Equipamento não magnético de ressonância magnética

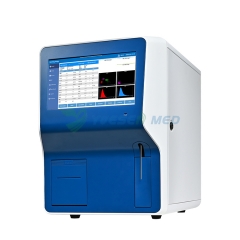

Processador de filme de grande capacidade

Item número.: YSX1504

Processador de filme de raio-X médico YSX1504 da China

Descrição

Large capacity x-ray film processor YSX1504

Product feature

Digital display to set the parameters and actual data. Touch-sensitive buttons make adjustments more easily set parameters simple.

In contrast, fixing, washing, unique among the flume design, and the developer will not only reduce across-contamination between the solution to enhance the use of chemical time. Deep trench design, the film also make washing a cleaner, richer level film, video effects better.

Processor speed, rinse 220 (theoretical impulse) pieces for 14”×17”per hour. Any hospital can fully meet the needs of the irrigation rate.

With high-intensity-type roll axis, ensuring safe delivery film, and to convenient day-to-day cleaning. Application of electronic temperature control and the jet wind road technology to ensure not air drying film.

1.Rinse width:minimun:3”×6”,maximum:14”×17”

2. Process time: 90~300s (full program), 25~70s (develop time)

3.Developer temperature:20℃~40℃(±0.3)(adjust)

4.Wash quantity:220 paper per hour,(14”×17”)、280paper per hour(10”×12”)

5.Dry temperature: 20℃~70℃(adjust)

6. Channel volume: 12.5L for develop, fixation and wash each one.

7. Washing control: to enter water 2~8L/min automatically.

8. Replenishment: 50~500ml/sq.m.each time (automatically and manually)

9. Power:200V/50Hz/8.8A 2000W

Unit packing size: 1050*720*1230(mm)

Pcs/Carton: 1pcs

G.W:120KG

LCD Control Pannel YSX1504

Product feature

Digital display to set the parameters and actual data. Touch-sensitive buttons make adjustments more easily set parameters simple.

In contrast, fixing, washing, unique among the flume design, and the developer will not only reduce across-contamination between the solution to enhance the use of chemical time. Deep trench design, the film also make washing a cleaner, richer level film, video effects better.

Processor speed, rinse 220 (theoretical impulse) pieces for 14”×17”per hour. Any hospital can fully meet the needs of the irrigation rate.

With high-intensity-type roll axis, ensuring safe delivery film, and to convenient day-to-day cleaning. Application of electronic temperature control and the jet wind road technology to ensure not air drying film.

1.Rinse width:minimun:3”×6”,maximum:14”×17”

2. Process time: 90~300s (full program), 25~70s (develop time)

3.Developer temperature:20℃~40℃(±0.3)(adjust)

4.Wash quantity:220 paper per hour,(14”×17”)、280paper per hour(10”×12”)

5.Dry temperature: 20℃~70℃(adjust)

6. Channel volume: 12.5L for develop, fixation and wash each one.

7. Washing control: to enter water 2~8L/min automatically.

8. Replenishment: 50~500ml/sq.m.each time (automatically and manually)

9. Power:200V/50Hz/8.8A 2000W

Unit packing size: 1050*720*1230(mm)

Pcs/Carton: 1pcs

G.W:120KG

LCD Control Pannel YSX1504

---------------------------------------------------------------------------------------------------------------------------------------------------------

YOUR MAY ALSO LIKE ...